Automobile Industry: The demand for copper wire in Automobile wiring harness workshops cannot be overemphasized. The automotive wire harness is simply a set of wires, terminals and connectors which runs through an entire vehicle. The wiring harness in automobile performs a very crucial part in the general functioning and reliability of the vehicle. The use of copper as the wire harness in automobile is owned to the properties of the metal, these properties include, ductility, high electrical conductivity and its dependability. Due to the intrinsic properties of Copper, it has a wide range of applications in the automobile industry. Some of these applications are:

v It is more suitable for applications that requires thinner gauge

v Copper is a metal that is easier to produce and also assemble into packed wire harness

v Copper wire harness generates less amount of heat during operation

v The corrosion of copper wire harness is low

v Copper wire has the capability of being bundled into small sizes

Aviation Industry: In the aviation or aerospace industry, aircrafts are usually designed to contain large number of wire harnesses. The importance of wire harness in aircrafts is that it is uses an assembly of electrical wires and cables to transmit electrical power and electronic signals throughout the aircraft. The wire used in the aviation industry is often a single and rigid conductor and it is usually stranded to reduce breakage due to flight vibrations and in-flight flexing. The Copper wire harness is used extensively for both commercial and military aircrafts. The applications of the wire harness in the aerospace industry include the landing gear, the fuselage, the engine, the wing and others.

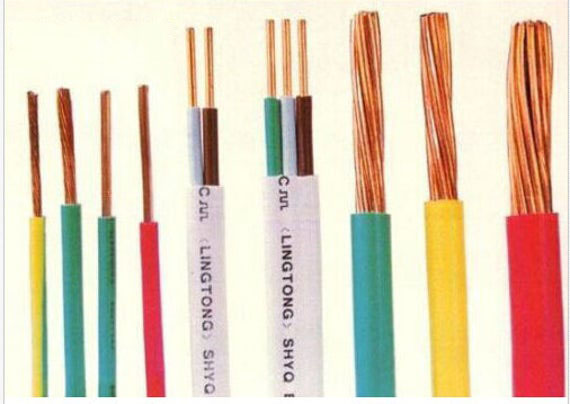

Electrical Systems: The use of Copper wire harness in electrical systems is prominent. The wires or cables which are made of the Copper metal are used to connect devices together, as this helps to transmit signals. Communication cables that travel over a long distance, especially undersea, also use the Copper wire harness for effective transmission. This Copper wire harness is mostly worked on using a wire crimping machine, coaxial cable stripping machine or a wire stripping machine. Also, the copper wire harness is used in electrical circuit boards and electric control boards. The wires are manufactured in the electrical workshops and are also tested under certain conditions. This test are carried out using specific tooling wiring harness machine such as wire terminal testers, and wire crimp pull testers.

Processing of Test Wires

The processing of wires requires you to remove the insulation from the metal. The wire stripping machine, the terminal crimping tool or the pneumatic wire stripping machine is easy to operate and they are manufactured in varying sizes and shapes, depending on the need and application. The steps involved in processing the test wires include;[aa1]

v Getting a suitable wire stripping machine: There are wide ranges of designs for wire stripping machines for different types of wires or cables. Some of the wire stripping tools have the semblance of a plier and some other will be huge machines. Hence, it is important to get the perfect machine that suits the particular wire you are working on.

v Matching the Notch to the wire gauge: Most wire stripping or crimping machine has a specified notch. A notch is a part of the machine in which you fix in the wire that is to be worked upon. It is paramount to match the wire gauge to the notch of the machine, this helps to make the processing of the wire easy.

Other steps that are needed to be followed in order to ensure the proper processing of the copper wire harness are;

v Ensure to place the wire perfectly into the notch

v Apply the required pressure on the handle, if its plier-like stripping tool. If it is a large machine, ensure not to exceed the necessary pressure

v Turn the crimping or stripping tool around the wire

v Remove the stripping machine off the wire to pull off the insulation

After the processing of the copper wire on the terminal crimping machine, there are usually waste materials or scraps obtained. It is expedient to understand that just like most metals, especially Iron and Aluminium, Copper scraps are recyclable. Whether it is wastes from the raw state of the metal or from manufactured products, the quality of the metal is still preserved. Copper, which is the third most recycled metal after Iron and Aluminium, has an 80% approximated volume of total mined material still in use, due to degree of how its scraps can be reused.