The New Energy Vehicle Wiring Harness

It

is the 21st century and there are new ideas and innovation in

different sectors with increasing technologies. Likewise, the manufacturers in

the automobile industry have added advanced and enhanced functions to the

production of vehicles, they produce vehicles with components through refined

processes in order to maximize space, increase efficiency and achieve other set

objectives. The experts and engineers who desire to bring innovative ideas in

the production of vehicles, especially in the electrical aspects and designing

of complex circuits, use advanced wiring harness equipment such as wire cutting

machine, harness machine, wire harness tools, cable crimping machine, etc. Most

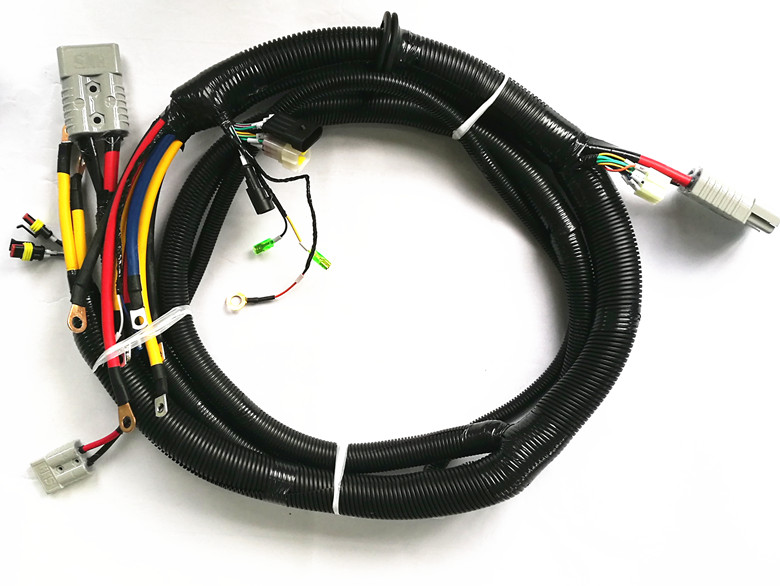

of these machines and equipment are used to make a wiring harness. A wiring

harness can be referred to as a set of well-arranged wires, connectors and

terminals which are connected within a vehicle and they are effective in

transmitting information electric power. The introduction of a new energy

vehicle wiring harness has played a vital role in linking various vehicle

components, hence, creating a network for the seamless transmission of information

and power similar to the circulatory and central nervous systems of the human

body.

The automotive wiring harness market is

accelerated by the ever advancing growth of the automobile industry which is

owed to the diverse level of new technologies and enhanced features which are

integrated in the production of vehicles. There are high rates of

competitiveness amongst the manufacturers of vehicles; the need to design

vehicles with exceptional features such as aesthetics, safety and electronic

gadgets. With obvious disparity from other typical wiring harness methods, the

new energy vehicle wiring harness offers safe, reliable and secured connections

throughout the vehicle. The incorporation of the new energy vehicle wiring

harness also proofs to be beneficial in that it improves the efficiency of the

fuel system of the vehicle. The new energy vehicle wiring harness is not

limited to any particular part of the vehicle, rather it can be applied to

different components and parts of a vehicle. These different components include

Body wiring harness, HVAC wiring harness, Engine wiring harness, Sensors wiring

harness, Chassis wiring harness and others. The new energy vehicle wiring

harness can be performed on various vehicle types such as the two and three

wheelers (Motorcycles and Tricycles), Passenger vehicles and commercial

vehicles. Also, manufacturers of aircrafts and other vehicles in the aviation

industry can also utilize the new energy vehicle wiring harness during the

design and production.

The processing of the new energy vehicle wiring harness is done sequentially. Firstly, the wires or cables will be cut to the manufacturers’ choice using a wire cutting machine. Secondly, the wires or cables are stripped bare at the ends and are then fitted into the desired connector or terminal casings. Then the wires or cables will be pulled together and braced on a workbench or using an assembly board, based on the requirements of the design. This forms the wiring or cable harness. The harness after fitting into the protective or insulation sleeves can then be used in a vehicle.

To perform these energy vehicle harness, you will need special cutting and stripping machines. These harness machines can be purchased on Cheers Electronics. Some of the machines which are available on the website for making the new energy vehicle wiring harness include the New Energy Cables Cut and Strip machine CSC-800XL and the No need change applicator tube-terminal crimping machine TFP-6C.

New Energy Cables Cut and Strip Machine CSC-800XL

The New energy cables cut and strip machine CSC-800XL is specially designed to cut new energy cables that are used in making wiring harness for vehicles. This machine can also be used for wire cutting and performing other processes which involves stripping. Regardless of the bulky size, the new energy cables cut and strip machine CSC-800XL is easy to operate and is built with features that limits the degree of labour the operator puts in. The machine has front and rear rollers alongside with an auxiliary device for ease of movement and carriage. It also has a four wheel drive stepper motor; it cuts and strips wires or cables at extreme speed and with high degree of accuracy. The machine can cut about 1500 Pcs of wires within an hour and also it can cut cables with great length up to 90000mm and width of 35-150sqmm. The display and graphic interface of the new energy cables cut and strip machine CSC-800XL is written in Chinese and English and it uses simple terms and terminologies that are easy to comprehend. It also has a good memory, where different levels of processing information are stored, this helps to ensure that the wire or cable materials are maximally utilized especially during bugging. Other specifications of the new energy cables cut and strip machine CSC-800XL includes;

v Power: 220V/50Hz, 110V/60Hz

v Function: Cutting wire, stripping both end, twice stripping

v Speed: 1500PCS/Hour (L=100mm)

v Stripping length: Front 1 – 500mm, End 1 – 150mm

v Dimension: 1000*600*1200mm

v Weight: 120KG

https://www.terminal-crimping.com/new-energy-cables-cut-and-strip-machine-CSC-800XL-9000.html

No need change applicator tube-terminal crimping machine TFP-6C

Another machine that can be used to design the new energy vehicle wiring harness is the No need change applicator tube-terminal crimping machine TFP-6C. This machine is a large Wire-end ferrules and a non-Insulated tube terminal crimping Machine that can cut wires and cables of about 120 sqmm in diameter. The machine has an engineering control chip that enables operations with high precision and this also gives the machine stability. The machine has a well-made and user-friendly design that is structured solidly, strong and with optimal performance. The machine is also easy to use and operate, the maintenance is also cost effective and it makes little noise during operation.

Other specifications of No need change applicator tube-terminal crimping machine TFP-6C includes:

v Power: AC 220V/ 50/60Hz, 2.3KW

v Cutting Speed: 800 – 1000 piece/hour (depends on operator’s proficiency)

v Crimping size: 10 – 120 sqmm

v Crimping force: 200KN

v Screw stroke: 350mm

v Crimping width or diameter: 12.5mm

v Dimension: 500*450*480mm

v Weight: 120KG